We are known in this industry for our service and quality because we do not compromise. We always welcome suggestions, queries with respect to quality up-gradation and packaging efficiency of cc boxes. Complaints from customers are rather treated as an opportunity for further improvement. Last but not least, our core business is trading of Kraft Paper in the name of M/S BALAJI PAPERMART which enables us to keep our promises in terms of QUALITY and TIME in corrugation industry.

Many years ago in England, corrugated paper, the ridged and grooved part of shipping and packaging boxes, was used as a liner for English top hats. However it wasn’t until 1871 that it was patented by Albert Jones of New York City for packaging purposes. Since then, corrugated paper has evolved from top hat liners into various cardboard box types, like pizza, bakery, and take-out boxes. Cardboard fluting is also used in some eco-friendly disposables, deli trays, paper plates, and disposable bakeware.

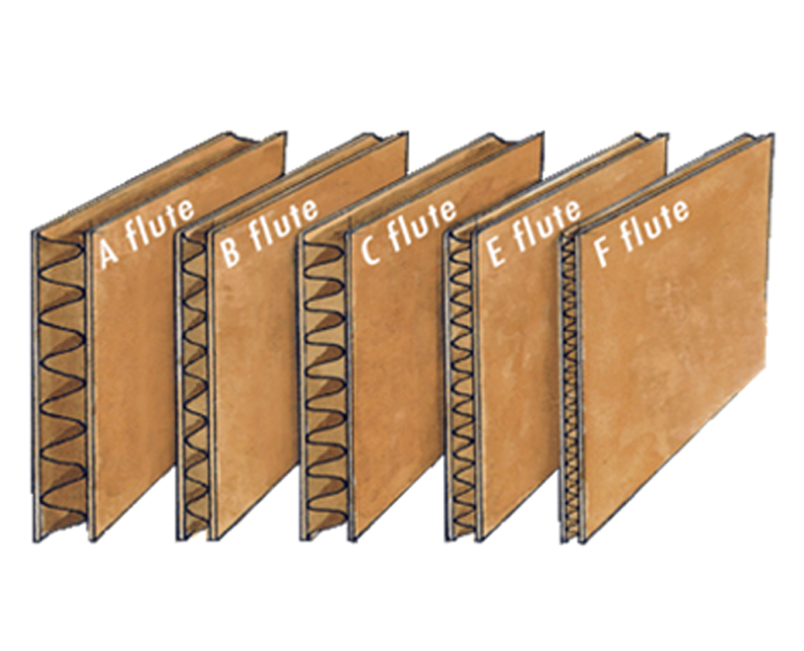

Sandwiched between two pieces of cardboard, the ridged flutes of these products are designed to support a great deal of weight. Not only is this beneficial for shipping purposes, but it also plays an important part in supporting the weight of food in the corrugated disposables mentioned above. This cardboard fluting construction also plays an integral role in protecting items during transportation.